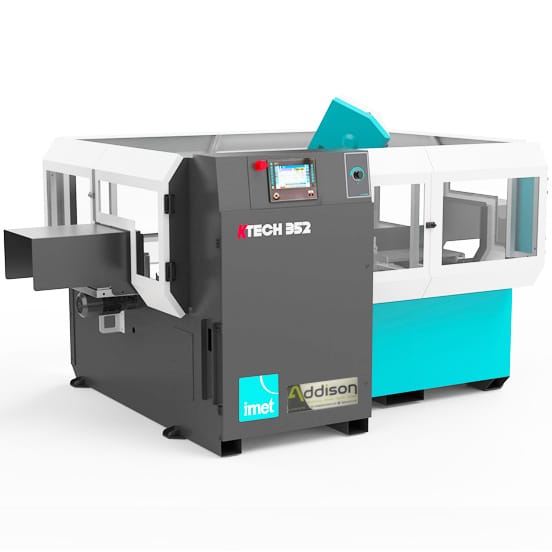

Imet Ktech 352 F1200 Automatic CNC Mitre Bandsaw

Automatic bandsaw with CNC control of the cutting parameters and two way powered mitre cutting function. This powerful bandsaw has a 305 mm cutting capacity for round metal materials and a capacity of 350 x 200 mm when cutting at 90 degrees.

The Ktech 352 is Ideal for production cutting situations where large quantities of differing lengths need to be cut from the same material stock. Highly recommended for structural steel applications and allows for bundle cutting with the optional bundle cutting vice add-on.

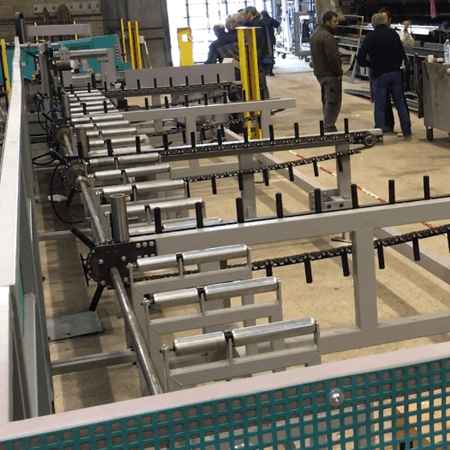

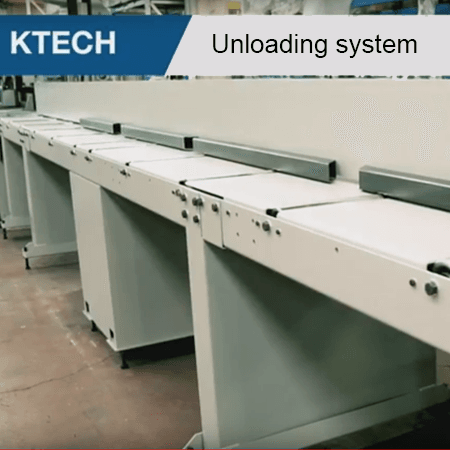

We also have a selection of roller tables available that are suitable for this machine. See the Roller Tables Tab for more information.

____________________________

Specification Table

| Cutting capacity at 0 ° | Round: 305 mm Square: 250 mm Rectangle: 350 x 200 mm |

| Cutting capacity at 45 ° left | Round: 255 mm Square: 230 mm Rectangle: 230 x 200 mm |

| Cutting capacity at 60 ° right | Round: 175 mm Square: 155 mm Rectangle: 170 x 100 mm |

| Bundle cutting capacity | Max: 300 x 160 mm; Min. 90 x 10 mm |

| Cutting capacity at 0 ° full (C45) | 200 mm |

| Blade size | 3370 x 27 x 0.9 mm |

| Blade motor | 1.8 KW |

| Blade speed | 15-100 m/min |

| Stroke of the feeder carriage | 1150 mm (repeatable) |

| Motor of the feeder carriage | 0.75 KW |

| Minimal scrap end | 150 mm |

| Hydraulic power unit tank capacity | 20 l |

| Coolant tank capacity | 100 l |

| Minimum length that can be cut | 20 mm |

| Maximum cutting/feed length | multiples of 1150 mm |

| Dimensions | 2935 x 2400 x 1900 mm |

| Weight | 2100 kg |

| Height of the work surface | TBA |

____________________________

Standard Features Overview

- HMI 10″ touch screen

- NC control

- Saw-frame movement

- Material feeder

- End of cut inclination

- Mechanical detection device

- F1200 integrated feeder

- Precision cutting through automatic correction of cutting lengths

- Minimal lubrication device

For more detailed standard feature information, see the standard features tab.

____________________________

Optional Features Overview

- Bundle Cutting Vice

- Chip Conveyor

- Battery Laser Line

- Industry 4.0 OneLoad Kit to allow the upload of data from an office environment via FTP

- Industry 4.0 RealTime Kit Upgrade for machine status, cut pieces situation, and automatic cycle progression via web service

- Industry 4.0 SAWFACTORY + RealTime Upgrade for remote management of the entire cutting process via a dedicated app

For more detailed optional features information, see the options tab.

____________________________

Addison are now offering WIKUS bandsaw blades – to see our selection visit the blade center here: Addison Bandsaw Blades