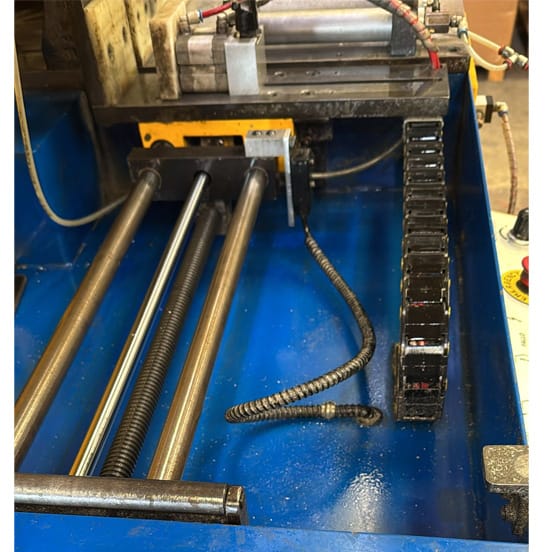

2010 Used Tronzadoras MG GAA 500-90

Automatic saw with pneumatic feeder for repetition 90deg cutting of non-ferrous metals. This competitively priced compact machine has been very well proven, and delivers consistent reliable performance. The 300mm feeder has a double index function as standard to cut up to 600mm. There is also an option for 9 times indexing if required. The machine can be configured during production with vertical and horizontal drilling/punching heads to produce simple finished components.

Serviced and cleaned, still holding perfect tolerance £3500.00 + vat excl delivery and installaition if required, no warranty offered.

Specification:

| Technical | GAA-500-90 | |

| Capacity 90° | Round | 150 mm |

| Square | 150 x 150 mm | |

| Rectangle | 250 x 75 mm | |

| Motor | 4,0 HP | |

| Blade Diameter | Ø 500 mm | |

| Blade Speed | 3000 RPM | |

| Blade Axis Diameter | 50 mm | |

| Maximum Cutting Height | 170 mm | |

| Feeder Advance Range | 500 mm (Double Advance) | |

| Pneumatic Clamps | 6 (3 Horiz + 3 Vert) | |

| Weight | 450 kg | |

| Dimensions | 1950 x 1050 x 970 mm | |

Cutting Chart: