- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

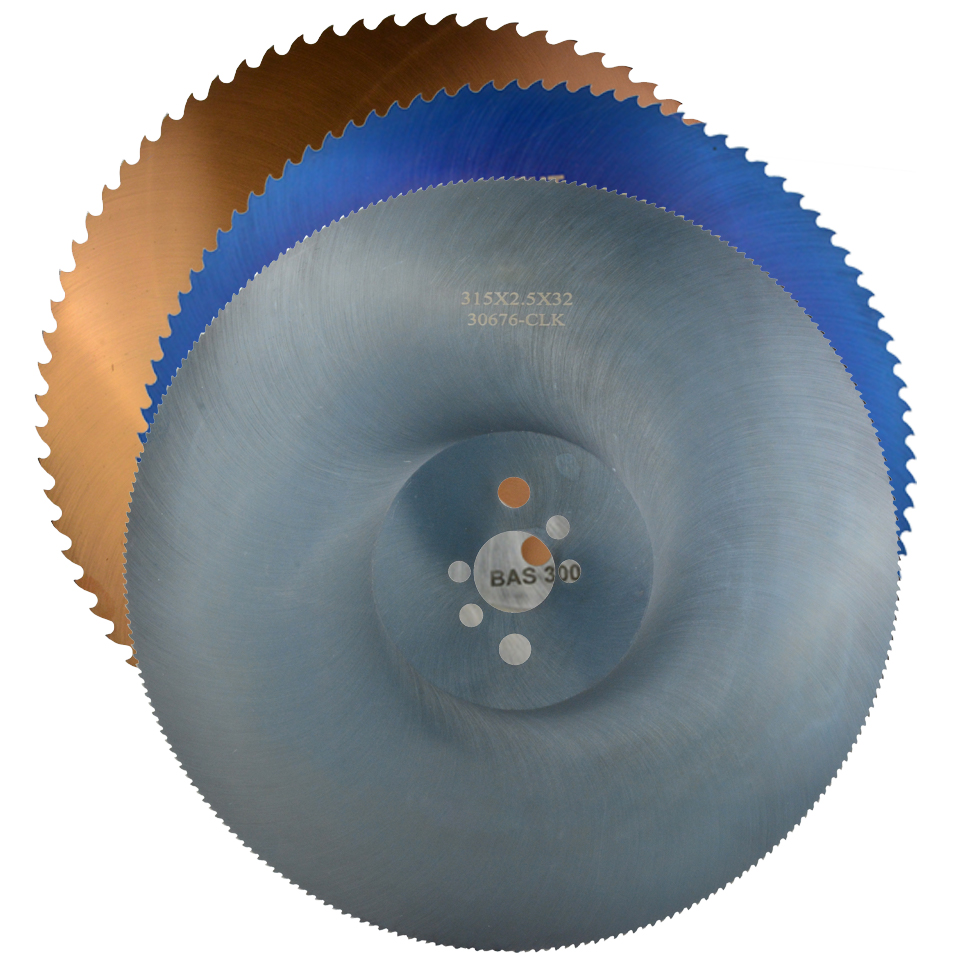

Specially formulated coatings for stainless steels, exotic metals and high performance applications.

Addison can supply all coatings in either M2 or M35 quality as blanks or toothed. Depending on the grade of material it is advised to change the front face and clearance angles on the teeth to suit your application.

(Physical Vapour Deposition)

PVD Coatings – TiN & TiCN. These coatings are applied to increase surface hardness, reduce friction and allow faster machining rates. These benefits vastly increase blade life giving you a lower cost per cut.

A popular coating applied to tooling for increasing surface hardness, lowering friction and retaining the cutting edge.

Much like the characteristics of TiN, this coating has higher resistance to abrasion and heat, allowing higher cutting rates.