- Used Machinery

- Steel Bandsaws & Circular Cold Saws

- PVC & Aluminium Machines

- Tube Bending Machinery

- Saw Blades & Lubricants

- Laser Cutting Machines

- Special Offers

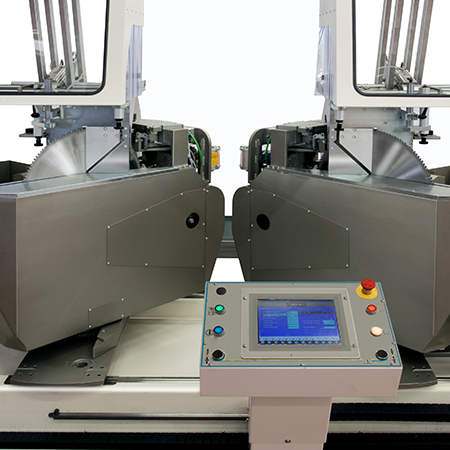

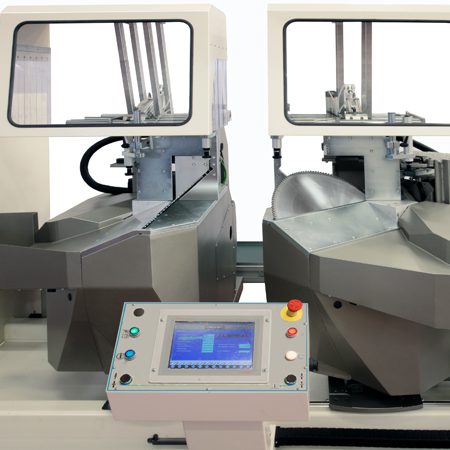

The all new Mecal TDC-622 is a unique machine combining the benefits of a rising blade 5 axis saw with the addition of linear feed to obtain an industry leading cutting capacity. The saw operates as a standard rising blade design. Once a material dimension wider than 200mm is input the unique sequence is activated where the saw blade advances forward underneath the saw table below the material, raises and retreats giving a massive 500mm width capacity. The machine is also equipped with a containment chute on each head to capture the off-cut pieces whilst a simple button press will empty the chute contents to the belt conveyor situated at the rear of the machine. The TDC-622 has clearly set a new benchmark for double mitre saws employing advanced design concepts to achieve higher performance, precision and reliability.

| Technical | Unit | |

| Max physical cut length (dependant on machine selesction) (90°) | mm | 5000 / 6000 |

| Cutting length (min. 90°) | mm | 470 |

| Blade diameter | mm | 600 |

| Sawblade bore | mm | 32 |

| Blade rotation speed | rpm | 2400 |

| Blade motor power | kW | 5,5 (x 2) |

| Installed electric power | kW | 14,5 |

| Overall dimensions (5 m. useful stroke) | mm | L/L=± 7780 L/W=± 2700 A/H=±1820/2100 |

| Weight (5 m. useful stroke) | kg | ± 3100 |

| Overall dimensions (6 m. useful stroke) | mm | L/L=± 8780 L/W=± 2700 A/H=± 1820/2100 |

| Weight of the machine (6 m. useful stroke) | kg | ± 3200 |